| |

|

|

|

|

|

| Diagram of thickness of materials which provide equivalent heat-insulation description::

|

material |

density

kg/м3 |

heat conduction

Вт/мК |

thickness comparative

мм |

|

|

|

|

Polyurethane |

25 - 300 |

0,020 |

40 |

|

|

|

|

polystyrene foam |

20 - 30 |

0,041 |

80 |

|

|

|

|

mineral cotton |

20 - 40 |

0,048 |

100 |

|

|

|

|

wood |

800 - 1000 |

0,130 |

274 |

|

|

|

|

haydite |

600 - 800 |

0,180 |

320 |

|

|

|

|

gas concrete |

800 |

0,220 |

400 |

|

|

|

|

brick |

1800 |

0,450 |

760 |

|

|

|

|

concrete |

2200 |

2,100 |

1720 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

Spraying of hard polyurethane foam(PPU) is the most effective technology of causing of heat-insulation coverages on-the-spot large area or surface with difficult relief. Spraying takes place by the special equipment straight on the object of customer. The got coverage shows by itself a jointless homogeneous cover from hard PPU, got as a result of mixing of two components at their coevaporation on a surface that is insulated. On the face of it technology of napyleniya is very alike with technology of painting of surface a sprayer. Hardening of coverage takes place in a flow 3 - 40 seconds. Spraying can be inflicted in a few layers to the required achievement of thickness of coverage which answers a heating engineering calculation.

Spraying from hard polyurethane was got by wide distribution at an isolation: houses of the industrial and civil setting (basements, sthenes, roof, ceilings, chaffs, internal partition, balconies and loggias); apartments of the agricultural setting (farms, hothouses and others like that); refrigeration and refrigerator chambers, including on a water-carriage; car refrigerator, isothermal containers and baskets of cars, internal partition, on a water-carriage; technological equipment, depositories, reservoirs, capacities.

Advantages of spraying talk for itself:

Economic efficiency. As practice, use of spraying, from hard polyurethane allows to economize approximately 50% facilities which outlay at application of traditional methods of heat-insulation.

First, due to unique heat-insulation properties of the hard polyurethane customer cardinally reduces capital charges on maintenance of the system of heat supply (in fact for heating the equipment of far less power is now needed и current outlays on power mediums (because for support of necessary temperature outlaid far less than heat-power engineering).

Secondly, a considerable economy is brought by the cost cutting on transporting, warehousing and editing of heat-insulation. Because any heat-insulation material on 85-90% consists of gas (air, carbonic acid and others like that), him it is far more comfortable and more advantageous to make applications straight on a place, what to drive «carriage or wagon with air» for hundreds, and even thousands of kilometres. It is possible to get from one ton of raw material (four barrel for 250 l) 20 м3 hard penopolyurethanea and to inflict him a layer in 3 - 4 see on an area 400 - 600 m2. Go out, for heat-insulation of such area in place of pair «Kamazov» from a 40 m3 prepared uteplitelya will be enough one «MINIBUS» with raw material and equipment onboard. Except for it, neither the enormous amount of timber and expense materials nor organization and guard of composition will not be needed.

Thirdly, a customer practically to the zero reduces charges on permanent and capital repairs of heat-insulation during all term of its service. In theory this term is estimated in 30 – 50 years. In practice recent researches of coverages from hard polyurethane, inflicted as early as 70-I years XX of age in the USA, Europe and Japan, showing absence of changes of useful properties of this material.

Fourthly, an insignificant density of hard polyurethane is 35 – 75 kg/m3 eliminates the additional loading on the isolated object, and goes out, rescues a customer from charges on strengthening of bearing construction of objects.

Fifthly, a loss is fully eliminated from vandalism and plunderings, and and expense, on the guard of mounted heat-insulation. In fact from hard polyurethane very hardness spraying to cause some harm and it is quite impossible to take off and take it with itself.

Technological profit.

Practical application of spraying from hard polyurethane on an order more technological from other methods of heat-insulation and saves to 80% to time at implementation of heat-insulation works.

First, time diminishes on loading, transporting and unloading of heat-insulation materials. To load four barrel with components and fluidizer spraying, to deliver them to the object and unloading is far simpler, than a 40 m3 prepared heat insulation.

Secondly, in once or twice the terms realization of work to shortly. A brigade from 2 persons is able to do a to 800 m2 spraying for changing, and the high-rate of hardening (consolidations) of material assumes exploitation of object practically at once after completion of work. The heat-insulation of such area requires traditional prepared of the heat isolation on an order large man-hour.

Thirdly, into the bargain to heat-insulation a customer at the use of spraying from hard polyurethane gets an additional sound-proofing, and by spraying with a density higher 65 kg/m3 yet and decides the tasks of waterproofing and corrosion preventing of the object. Can boast such multifunction none of traditional heat isolation.

Fourthly, high adhesion of hard polyurethane to any materials enables spraying him practically on any surface, in spite of angle of its slope, even on ceiling! Coverage which appears, from hard polyurethane densely fits snugly objects with any relief and accepts their form, that does not require planarizing under an isolation.

Fifthly, the ecological cleanness of spraying from hard polyurethane considerably facilitates his editing and exploitation, and chemical and biological firmness assumes his use under act of aggressive environment.

Application of elements from hard polyurethane is approved supervisory organization, to what testify:

- Hygienical certificate on products;

- Conclusion of fire laboratory.

|

|

|

|

| |

|

| |

|

|

|

Warming spraying of polyurethane (PPU).

Warming of roof.

The use of polyurethane for the isolation of roof found a wide use in the countries of Western Europe and USA during the last 25 years. A basic idea and decision advantage of this method consists in that except for spraying of heat-insulation pressurizing of roof is produced, while in the case of ordinary flat roof it is needed it would be to pawn a few layers of different materials which execute a different function. (look diagram of thicknesses of materials).

Only one material is used in the considered method - polyurethane, that simplifies building of roof considerably. By polyurethane, spraying inflicted a method, it is possible to cover majority of roof heat-insulation, and at the reconstruction of roof the heat-insulation can be inflicted even without dismantling last.

Temperature firmness of spraying materials for a flat roof makes from -180 °With to +120 °With, absorption of water material makes approximately 2% on volume. After the 8-hours contact of polyurethane with water the last must not penetrate deep. The coefficient of resistance diffusion of aquatic pair for polyurethane makes approximately 50. Calculation values of heat-conducting of polyurethane for spraying on a roof makes as for many other products from his without diffusion-dense layers coverage 0,02 W/(m2 o K). Measured value of heat-conducting at a temperature +10 °With does not exceed a size 0,023 W/(m2 oK).

At coverage of roof hard foam polyurethane a crust appears on his external surface. Due to a sun ultraviolet afterwards polyurethane acquires coverages brown colors. Mechanical properties of polyurethane coverage do not change at decolorizing. To get beautiful firmness to the weather terms, the external surface of penomateriala must be protected from an ultraviolet or by painting, or backfilling from a hoggin with the group of grittiness from 16 to 32 mm in thick no less than 5 cm. The gravel back filling must not be chemically treated, as, for example, against fungi, wreckers and others like that. Inflicting a few layers, it is possible to get heat-insulation of necessary thickness. Such technique of process of spraying enables making jointless, air-tight from water and heat-insulated surface.

At an ordinary flat roof it is possible from the structural considering on a cold side to inflict no protecting from a pair. On that ground protecting from a pair beds under heat-insulation, because an aquatic pair does not get to foam and runback can not appear.

Thus, polyurethane, as a modern heat-insulation build material, it is possible to apply not only for heat-insulation of joints of external wall and gaps between window and door blocks, floors of ground floors and ceilings above the not heated apartments, external wall, but also for heat-insulation of roof. Especially it touches a that roof, loading on which must be minimum.

Application of polyurethane (PPU) for warming and waterproofing of roof enables to insulate the roof of any complication and form, creating continuous jointless coverage (including joining). vapor permeabilty polyurethane (PPU) is insignificant, because content of the closed pores makes no less in him 95-98%. Causing of material can take place both on a new construction and on old, covered a metal, ruberoid or slate. Dismantling of old coverage and preparatory work it is not needed. The inflicted coverage does not require renewal and repair during all term of service of house. Components does not support burning and are heavily combustible. |

|

| |

|

| |

|

|

|

|

Polyurethane

Polyurethane(ППУ) are for today one of the widely widespread polymeric made foam materials which found application practically in all industry of industry. It – one of effective insulants with wide functional possibilities. Wares from polyurethane can be got in number of different ways with the use of machine of high and low pressure, spray installations.

Hard spraying polyurethane foam plastics are used as a heat - hydro- and underseal on metallic, wooden, concrete, plastered and to other surface.

-

Possibility of receipt of hard polyurethane with a different closeness (from 25 to 250 kg/m3 and more) allows to use him and as heat-insulation material, and as a construction. Hard polyurethane has on 95-98% physoclistous structure. At exploitation in normal terms hard PPU save the properties in a flow 25-50 years.

- Hard polyurethane of the heat-insulation setting it is possible to get directly in place of their causing of spraying or filling method in a cavity.

Hard polyurethane, in-use as heat- hydraulic- protective coverages, distinguishes the row of indisputable advantages before other heat-insulation materials:

- low coefficient of heat-conducting within the limits of 0,02...0,023 W/m2 o K;

- high heat- and frost-resistance (from -180 to +120 °С);

- high adhesion to different materials;

- firmness to the action of microorganisms and aggressive environment (salt water, benzol, petrol, diesel fuel, vegetable and animal fats, acid and grounds, shale-gases);

- high mechanical descriptions;

- absence of current outlays on periodic repair and renewal of the damaged heat-insulating coverages;

- ecological safety during exploitation;

- considerable resource (25...50 years).

Shallow physoclistous structure hard spraying polyurethane allows to get multi-layered jointless coverages of necessary thickness, which provide low heat loss and good waterproofings properties.

The receipt of heatcover coverages is carried out on a two-component schema. As a feedstock is used component of necessary compounding composition (component "A") and polyisocyanate (component "B"), on the basis of which it is possible to get polyurethane materials with necessary properties. Correlation of components "A":"B" for a different brand polyurethane is scope from 1:1 to 1:2.

For the receipt of polyurethane coverages raw material is used both imported and domestic, productions. Polyisocyanate of component (component "B") is used the mainly imported production (Germany, Japan, USA, Belgium, Holland, Spain).

|

|

| |

|

| |

|

|

|

|

REFRIGERATOR BOX

INTERNATIONAL CLASSIFICATION - CLASS FRC.

UP TO = 0,025 Vт/m2 0К.

Refrigerator baskets, intended for transportation of loads which require especially exact and assured control climate in the process of transporting and storage. Can be used for transportation of loads of any complication, in any climatic terms.

Repair of lateral side and roofs conducted on beskarkasniy technology which eliminates a presence "bridges of cold":

- thickness of panels: roof - 80mm;

- front wall - 80mm;

- lateral walls - 50mm;

- heat-insulation material – poltyrethane, by a closeness 65 kg/m3.

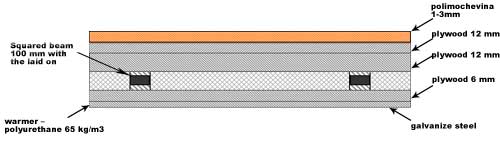

Floor - five layers glued continuous (not attach) sendvich-panel of extra-strong for providing of possibility of leadthrough of dock works of 5 by a ton loader. The panel of floor is agglutinate single-component by poliurethane glue. Thickness of floor 135 mm. Coverage of floor into a basket – polyiurethanes or polimochevinnaya inundation with addition of quartz sand. Thickness of coverage 3 mm. For protecting from atmospheric influences from the side of stretcher (exterior of floor of basket) – a steel sheet is zincked. Heat insulation material – by a penopolyurethane closeness 65 kg/m3.

Floor structure:

Doors - like walls (see is higher repair and obrobka sthenes).

Additional options:

- coverage of floor - rifle steel pallet, rifle aluminium pallet 1-3 mm of polimochevina;

- furniture - imported zincked, imported non-rusting;

- internal partition;

- spreading of the outdoor advertising;

|

|

|

|

|